Description

DTI

DTI 5000

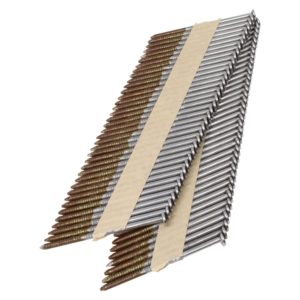

- These machines are custom designed for vertical applications with the nose piece jaws fitting the customer’s part. The inline screwdriver assemblies can be designed for a wide range of applications and fastener types including screws, bolts, nuts, pins, or nails.

Features:

- The standard screw feeder system cycles quickly delivering screws in less than one second in many applications.

- The rigid units maintain contact between the bit and the fastener in order to locate the screw in predrilled or misaligned holes.

- This system retracts the barrel fully when the driver starts, so that the driver components do not contact the work surface when the screw is driven.

- The counterbore tip designs are ideal for screws located in counterbored or recessed holes. These drivers can accommodate various counterbore hole depths as well.

- Auto shut-off clutch

- Adjustable settings for the feed blow time, bowl run time, barrel retract and extend time, and driver shut-off time in drive-to-depth applications

- Designed for ease of maintenance